New Holland TN75FA, TN85FA, TN95FA Tractor Service Manual

$137.50

Covers: New Holland TN75FA, TN85FA, TN95FA Tractor

Pages: 1,460

Format: PDF file

File size: 43mb

Compatibility: Windows/Mac/Tablet

Notes: Instant digital download only – no printed copy or CD-ROM media.

The New Holland TN75FA, TN85FA, TN95FA Tractor Service Manual PDF contains over 1,400 pages of detailed OEM maintenance, service, repair, adjustment and troubleshooting procedures for the tractor. Whether you are performing mechanical, hydraulic or electrical repairs, this publication is essential to safely and accurately service the TN-FA series tractor.

Latest edition. Diesel engine repair is included.

Topics:

GENERAL INFORMATION

ENGINE

- Specifications

- Description and Operation

- Special Tools

- Tightening Torques

- Sectional Views

- Troubleshooting

- Overhaul

- Engine Removal/Installation

- Compression Test

- Disassembly

- Assembly

- Seal Installation

- Checks, Dimensions and Repairs

- Cylinder Block

- Crankshaft

- Main Bearings

- Flywheel

- Connecting Rods

- Pistons

- Valves

- Valve Timing

- Camshaft

- Tappets

- Cylinder Head

- Valve Seats

- Valve Guides

- Crankshaft Front Oil Seal

- Rotating Counterweight Dynamic Balancer

- Valve/Rocker Arm

- Cooling System

- Radiator

- Thermometer

- Thermostat

- Thermostatic Switch

- Overhaul

- Coolant Pump

- Drive Belt Tension Adjustment

- Cooling System Thermostat

- Radiator

- Lubrication System

- Oil Filter

- Low Oil Indicator

- Fuel System

- Fuel Injection Pump (Bosch)

- Turbocharged Models

- Overhaul

- Fuel Injectors

- Injection Pump

- Checking the Fuel Injection Pump Timing with the Pump on the Tractor

- Lock-time the Fuel Injection Pump with the Pump Removed from the Tractor

- Fuel Circuit Air Bleeding

CLUTCH

- Clutch Removal/Installation

- Dual Disk Clutch 11″/11″ Test Bench Overhaul

- Single Disk Clutch 11″ (installed with Power-Shuttle) Test Bench Overhaul

- Checks, Measurements and Repairs — Dual Clutch

- Coplanarity Adjustment of 11″/11″ Dual Clutch Release

- Coplanarity of 11″ Single Plate Clutch Release Levers

- PTO Clutch Servo Assist

- PTO Clutch Control System and Adjustment

TRANSMISSION

- Mechanical Transmission (16 x 16) Synchro-Command

- Main data

- Torque settings

- Tools

- Cross-sectional views

- Description and operation

- Troubleshooting

- Rear transmission/gearbox casing Removal, Installation

- Gearbox transmission casing Disassembly, Assembly

- Transmission Gearbox Casing

- Gearbox control lever Removal, Installation

- Range gear control lever Removal, Installation

- 32 x 16 Dual Power with Electrohydraulic Power Shuttle

- Main Data

- Torque Settings

- Tools

- Description and operation

- Transmission Gearbox Disassembly, Assembly

- Clutch Casing Disassembly, Assembly

- Power Shuttle Control Valve Disassembly, Assembly

- Accumulator Disassembly, Assembly

- Power Shuttle Transmission Calibration, Faults and Diagnostics

FWD TRANSFER BOX AND AUTO FWD

- Main Specifications

- Tightening Torques

- Tools

- Cross-Sectional Views

- Description and Operation of the FWD Drive Gear

- Troubleshooting

- Transmission Shafts and Guard, Removal–Installation

- Drive Gear Housing, Removal–Installation

- Drive Gear Housing, Disassembly–Assembly

- Auto FWD, Calibration and Diagnostics

FRONT AXLE (Super Steer Axle)

- Front Axle

- Main Data

- Torque Settings

- Tools

- Cross-Sectional Views

- Description and Operation

- Troubleshooting

- Front axle assembly removal, installation

- Bevel drive and front axle differential housing removal, installation

- Front axle bevel drive overhaul

- Front axle differential overhaul

- Front axle differential lock clutch assembly. Overhaul

- Front epicyclic final drive. Removal–Installation

- Wheel hub and steering knuckles. Removal–Installation

- Steering knuckle pins and bearings. Replacement

- Front wheels adjustment (Toe-in)

REAR MECHANICAL DRIVE

- Main Data

- Tightening Torques

- Tools

- Cross-Sectional Views

- Description and Operation

- Troubleshooting

- Rear Transmission Gearbox Removal, Installation

- Differential Lock Engagement Sleeve Adjustment

- Final Drive Box Assembly Removal,Installation

- Drive Shaft Removal, Installation

- Epicyclic Final Drive Removal, Installation

MECHANICAL PTO

- Main Data

- Troubleshooting

- Tools

- Tightening Torques

- Independent PTO Description and Operation

- PTO Servo-Assist Valve Description and Operation

- PTO Clutch Engagement/Oil Flow

- PTO Clutch Disengagement/Oil Flow

- PTO Clutch Servo Control Adjustment

- Hydraulic PTO Servo Assist Cable Adjustment

- PTO Engaged Switch Adjustment

- Mechanical PTO Removal, Installation

- PTO Brake

BRAKES

- Main Data

- Torque Settings

- Cross-Sectional Views

- Tools

- Description and Operation

- Troubleshooting

- Right or Left-Hand Brake, Removal, Installation

- Brake Hydraulic Pump (Master Cylinders), Removal, Installation

- Brake Hydraulic System, Air Bleeding

- Parking Brake Disks, Removal, Installation

- Handbrake Control, Stroke Adjustment

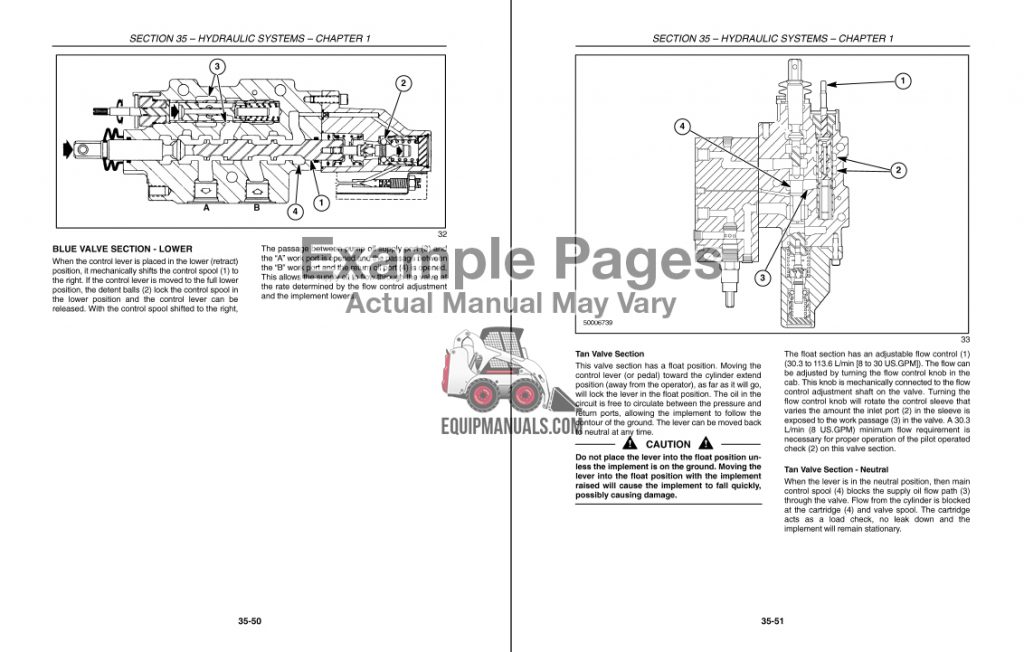

HYDRAULIC SYSTEM

- High Pressure System Description and Operation

- System Diagrams

- High Pressure System Overhaul and Adjustment

- Low-Pressure System Description and Operation

- Low-Pressure System Test Fitting Locations

- Front Electronic Lift and Front PTO

- Description and Operation of the Electronic Service Tool (EST) with the Front PTO and Hydraulic Power Lift (HPL)

STEERING

- Main Data

- Torque Settings

- Tools

- Description and Operation

- Troubleshooting

- Hydrostatic Steering Control Valve. Removal, Installation, Disassembly, Assembly, Testing

- Open Center Fixed – Displacement Steering Pump

Axles and Wheels

- Main Data

- Cross-Sectional Views

- Tightening Torques

- Torque Settings

- Tools

- Troubleshooting

- Front Axle Hub, Disassembly, Assembly

- Front Axle, Removal, Installation

- Stub Axle, Overhaul

- Checking Front Wheel Alignment (Toe In)

CAB CLIMATE CONTROL

- Cab Air Conditioning System Safety

- Use of the Air Conditioning System

- Tools and General Characteristics

- Operating Principles

- Main Components of the Cab Air Conditioning System

- Cab Heating and Ventilation Controls

- Cab Air Conditioning and Temperature Controls

- Function and Cooling Tests

- Maintenance of the Air Conditioning System

- Troubleshooting

- Refrigerant Recovery – Recycling and Evacuation – Charging Stations

- Filter/Drying, Recharging and Refrigeration Check

- Checks and Elimination of Gas Leaks

- Compressor Drive Belt Tension Adjustment

- Cab Air Vents Removal and Installation

- Air Conditioning Unit Removal and Installation

ELECTRICAL SYSTEMS

- Instruments

- Components

- Starting System

- Charging System

- Battery

- Connectors

- Wiring Diagrams, Electrical Schematics

CAB, PLATFORM, AND BODYWORK

Have any questions or need more details? Contact Us

Reviews

There are no reviews yet.