Caterpillar C10, C12 (1YN, 2PN) Diesel Engine Service Manual Set

$44.99

Covers: Cat C10, C12 diesel engine with 1YN or 2PN serial number prefix

Pages: 266

Format: PDF file

File size: 8mb

Compatibility: Windows/Mac computers

Notes: Instant digital download only – no printed copy or CD-ROM media.

This downloadable 4-volume PDF service manual set contains specifications, service and rebuild procedures, operating, and testing/adjusting information for the Caterpillar C10, C12 (1YN, 2PN diesel engines. Over 200 pages of the detailed OEM information for the engine are included in this download. The service manual set follows the manufacturer’s standards for service and repair, and is a must for all diesel mechanics. All pages are searchable and printable. View pages on your computer or print them off for the shop without worrying about dirtying an expensive book, saving your business time and money.

This download includes:

- 1YN1-Up, 2PN1-Up Specifications

- 1YN1-Up, 2PN1-Up Systems Operation, Testing and Adjusting

- 1YN1-Up, 2PN1-Up Disassembly and Assembly

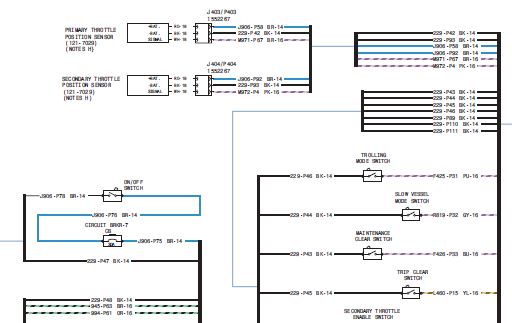

- 1YN 2PN Wiring Schematic

Specifications Section

Engine Design

Fuel Transfer Pump

Fuel Lines

Fuel Filter (Primary)

Fuel Filter and Water Separator

Electronic Unit Injector

Electronic Unit Injector Mechanism

Electronic Unit Injector Rocker Arm

Electronic Unit Injector Wiring

Lifter Group

Rocker Shaft

Valve Mechanism

Valve Mechanism

Valve Rocker Arm

Valve Mechanism Cover

Cylinder Head Valves

Cylinder Head

Compression Brake

Compression Brake

Turbocharger

Exhaust Manifold

Camshaft

Engine Oil Filter Base (166-1329 Oil Filter Base)

Engine Oil Pump

Engine Oil Pressure

Engine Oil Pan

Coolant Conditioner Base

Water Temperature Regulator

Cylinder Block

Cylinder Liner

Cylinder Liner Projection

Crankshaft

Crankshaft Seals

Vibration Damper and Pulley

Connecting Rod Bearing Journal

Main Bearing Journal

Connecting Rod

Piston and Rings

Piston Cooling Jet

Housing (Front)

Gear Group (Front)

Rear Power Take-Off (RPTO)

Flywheel

Flywheel Housing

Engine to Transmission Adapter

Belt Tension Chart

Belt Tensioner

Auxiliary Drive Pulley

Fan Drive

Alternator and Regulator

Electric Starting Motor

Electrical Ground Stud

Coolant Temperature Sensor

Fuel Temperature Sensor

Engine Oil Pressure Sensor

Boost Pressure Sensor

Atmospheric Pressure Sensor

Inlet Air Temperature Sensor

Speed and Timing Sensor

Accelerator Pedal Position Sensor

Systems Operation Section

Engine Design

General Information

Glossary of Electronic Control Terms

Electronic Control System Components

Fuel System

Air Inlet and Exhaust System

Lubrication System

Cooling System

Basic Engine

Rear Power Take-Off (RPTO)

Compression Brake

Electrical System

Testing and Adjusting Section

Fuel System

Electronic Control System

Air Inlet And Exhaust System

Lubrication System

Cooling System

Basic Block

Compression Brake

Electrical System

Belt Tension Chart

Disassembly and Assembly Section

Summary of Revisions

Fuel Priming Pump – Remove and Install

Fuel Filter Base – Remove and Install

Fuel Transfer Pump – Remove

Fuel Transfer Pump – Install

Fuel Manifold – Remove

Fuel Manifold – Install

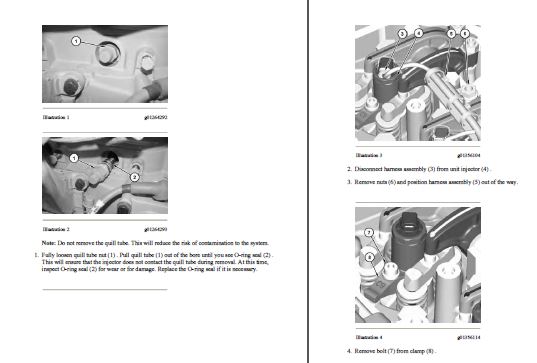

Electronic Unit Injector – Remove

Electronic Unit Injector – Install

Electronic Unit Injector Sleeve – Remove

Electronic Unit Injector Sleeve – Install

Turbocharger – Remove

Turbocharger – Install

Exhaust Manifold – Remove and Install

Inlet Manifold – Remove

Inlet Manifold – Install

Inlet and Exhaust Valve Springs – Remove and Install

Inlet and Exhaust Valves – Remove and Install

Inlet and Exhaust Valve Guides – Remove and Install

Inlet and Exhaust Valve Seat Inserts – Remove and Install

Engine Centrifugal Oil Filter – Remove and Install

Engine Oil Filter Base – Remove

Engine Oil Filter Base – Disassemble

Engine Oil Filter Base – Assemble

Engine Oil Filter Base – Install

Engine Oil Cooler – Remove

Engine Oil Cooler – Install

Engine Oil Pump – Remove

Engine Oil Pump – Disassemble

Engine Oil Pump – Assemble

Engine Oil Pump – Install

Water Pump – Remove

Water Pump – Disassemble

Water Pump – Assemble

Water Pump – Install

Water Temperature Regulator – Remove and Install

Water Outlet Manifold – Remove

Water Outlet Manifold – Install

Flywheel – Remove

Flywheel – Install

Crankshaft Rear Seal – Remove

Crankshaft Rear Seal – Install

Crankshaft Rear Seal Carrier – Remove and Install

Flywheel Housing – Remove and Install

Rear Power Take-Off (RPTO) – Remove

Rear Power Take-Off (RPTO) – Install

Vibration Damper and Pulley – Remove and Install

Crankshaft Front Seal – Remove

Crankshaft Front Seal – Install

Front Cover – Remove

Front Cover – Install

Gear Group (Front) – Remove

Gear Group (Front) – Install

Housing (Front) – Remove

Housing (Front) – Install

Accessory Drive – Remove

Accessory Drive – Disassemble

Accessory Drive – Assemble

Accessory Drive – Install

Valve Mechanism Cover – Remove and Install

Valve Mechanism Cover Base – Remove and Install

Compression Brake – Remove

Compression Brake – Disassemble

Compression Brake – Assemble

Compression Brake – Install

Rocker Shaft and Pushrod – Remove

Rocker Shaft – Disassemble

Rocker Shaft – Assemble

Rocker Shaft and Pushrod – Install

Cylinder Head – Remove

Cylinder Head – Install

Lifter Group – Remove and Install

Camshaft – Remove

Camshaft – Install

Camshaft Gear – Remove and Install

Camshaft Bearings – Remove

Camshaft Bearings – Install

Engine Oil Pan – Remove and Install

Cylinder Liner – Remove

Cylinder Liner – Install

Piston Cooling Jets – Remove and Install

Pistons and Connecting Rods – Remove

Pistons and Connecting Rods – Disassemble

Pistons and Connecting Rods – Assemble

Pistons and Connecting Rods – Install

Connecting Rod Bearings – Remove

Connecting Rod Bearings – Install

Crankshaft Main Bearings – Remove

Crankshaft Main Bearings – Install

Crankshaft – Remove

Crankshaft – Install

Crankshaft Gear – Remove and Install

Bearing Clearance – Check

Coolant Temperature Sensor – Remove and Install

Engine Oil Pressure Sensor – Remove and Install

Speed/Timing Sensor – Remove and Install

Belt Tensioner – Remove and Install

Engine Control Module – Remove and Install

Alternator – Remove and Install

Electric Starting Motor – Remove and Install

Air Conditioner Support Bracket – Remove and Install

Air Compressor – Remove and Install

Air Compressor Drive Gear – Remove

Air Compressor Drive Gear – Install

Foldout Size Wiring Schematics

Engine Harness Wiring Diagram

OEM Vehicle Harness Wiring Diagram

Basic Electrical Troubleshooting and Diagnostic Code List

Index

How does this work?

It’s simple – after purchasing this manual through our secure checkout, a download link will be sent to the email address you specify at checkout. You have up to 90 days to retrieve and save the file. Once saved, the manual is yours for good.

Have any questions or need more details? Contact Us